Weldment Configurations

Weldment Configurations

The basic joint often is changed to assist in a component’s assembly. A weld joint might be modified to gain access to the weld joint or to change a weld’s metallurgical properties. Some common weldment configuration designs are described below.

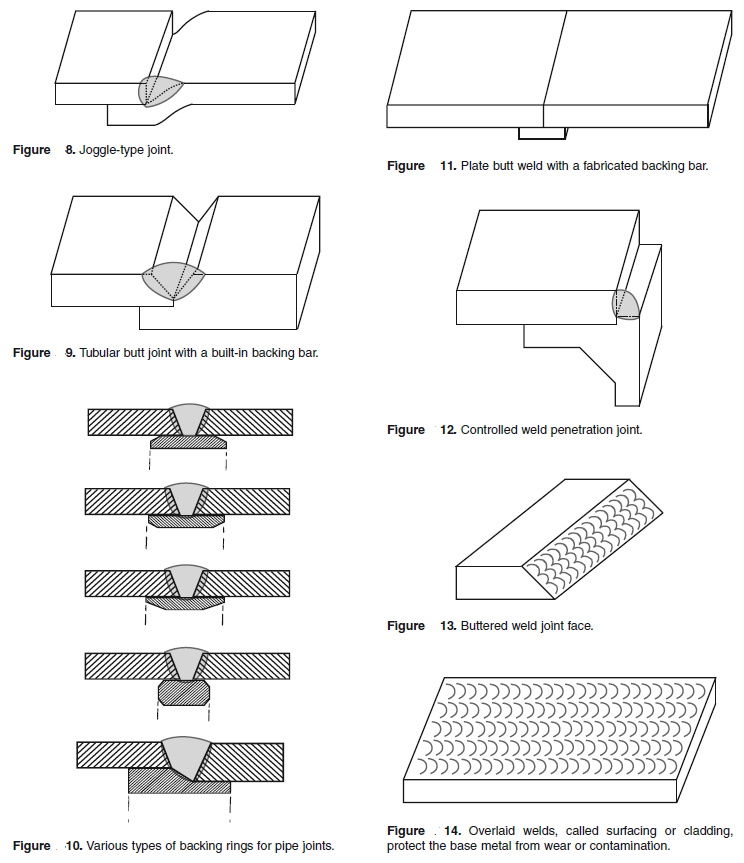

Joggle-type joints are used in cylinder and head assemblies where backing bars or tooling cannot be used. See Figure 8 below.

Another application of joggle joints is in the repair of unibody automobiles where skin panels are placed together and welded. A built-in backing bar is used when enough material is available for machining the required backing or when tooling cannot be inserted (as in some tubular applications). An example in which tubing is being joined to heavy wall tube is shown in Figure 9.

Pipe joints often use special backing rings or are machined to fit specially designed mated parts. Types of backing rings are shown in Figure 10. Figure 11 shows a fabricated backing bar. These bars must fit tightly or problems will be encountered in heat flow and penetration.

Weld joints specially designed for controlled penetration are used where excessive weld penetration would cause a problem with assembly or liquid flow. This type of joint is shown in Figure 12.

A series of bead welds overlaid on the face of a joint is called buttering, Figure 13. Buttered welds are often used to join dissimilar metals.

A series of overlaid welds on the surface of a part to protect the base material is called surfacing or cladding, refer to Figure 14